CMMS and Reliability

You can acheive maintenance effectiveness through "good" information.

Using Your CMMS for Reliabilty Analysis

Good historical information tells us “what happened” in the time leading up to and at failure. It is the synthesis of tombstone data, "as-found" data, condition data, and operational and maintenance data (equipment events and minor maintenance). Systematically gathered and formatted historical data will usually reveal knowledge with which maintenance personnel may subsequently make optimal scheduling and on-condition maintenance decisions.

Key issues regarding historical data:

- A sufficient number of complete life-cycles[1] of a system (significant item/component) must be available for analysis - the basic requirement.

- Failures with safety, environmental, or serious economic consequences will usually be designed out at their first occurrence and are not candidates for historical analysis

- Voluminous amounts of data can often be found where the consequences of failure are of minor importance, – but in those cases it is not worthwhile either to collect it nor to analyze it.

- That leaves the middle range. Failures in this category may account for between 40 and 80% of the average maintenance budget. Optimizing inspection schedules and CBM interpretive models for this group of failures will pay huge dividends.

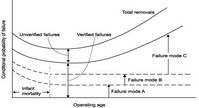

Figure 1

We observe that the “Total removals” line resembles the famous “bathtub” curve (once thought to describe the majority of failures). However, other information (available from a CMMS) empowers us to delve deeper and extract some very useful knowledge. The term “unverified” in the graph means that no particular failure mode (failure cause) could be attributed to a failure. Each line in this graph represents the risk (conditional probability of failure) due to one or more failure modes. The lowest dotted line tell us that failure mode A has an initially high and decreasing risk of failure. The dashed line above it represents the combined risk of failure by both failure modes A and B. We note that failure mode B occurs randomly, that is its conditional probability of failure is constant (the initial curvature is due to that of failure mode A). By making such distinctions (that is, identifying the failure mode on the completed work order where possible) in our CMMS database, reliability analysis tools, such as this graph, draw our managerial attention to, in this instance, material quality or installation errors. Furthermore, we note that failure mode C exhibits random failure behaviour until a certain age (known as its useful life), whereupon it begins to wear out. Once again this knowledge, if concealed by incomplete or inconsistent maintenance reporting, will be rendered ineffectual, denying us the opportunity to consider redesign or possible task schedule changes that address failure mode C or its consequences.

Historical CMMS data is, without doubt, fertile ground in which to sow the seeds of reliability analysis. The question is often asked, “How much data do I need?”. It varies. The CBM optimizing tool, EXAKT, builds a CBM optimal decision model that uses both the CMMS and the CBM data. The software analyzes and correlates the data from each of these databases, builds a model, and ascribes a confidence level for the model’s ability to predict remaining useful life. The “goodness” of the model depends on two factors: 1. How indicative of the target failure mode are the variables that you are monitoring, and 2. How much data (i.e. number of life cycles) do you have? “Better” condition indicators require less historical data to produce a confident decision model.

From the foregoing we may conclude that an equipment’s recorded history, as collected in the CMMS, can be very valuable indeed – but only if it is accessible, consistent and accurate. There are two kinds of data needed for analysis: 1. CBM data (pressures, temperatures, vibration readings, oil analyses, and so on), and 2. Historical event data (operational and maintenance). There are hardly ever any problems associated with the former. It is nearly always well-structured and consistent. The latter, on the other hand, represents one of the most difficult challenges in maintenance information management. How shall we describe our observations when we perform a repair or scheduled task, in a consistent format and language, so that they may be analyzed using reliability software? We are all familiar with the drop down lists of fault codes in the CMMS’s and EAM’s. And we all know that the top few on the list attract the most votes! The use of fault codes has not lived up to our expectations because they seldom provide sufficient knowledge about "what happened". Can we do better? The concise language of RCM offers a means to a rich and accurate historical database.

Learning to use an RCM data model in the course of everyday maintenance reporting will reap multiple rewards: 1. Common database tables for on-going RCM analyses and everyday data reporting will accelerate global assimilation of "RCM thinking", 2. Data integrity will benefit from instantaneous validation of well formed failure descriptions, states, causes, effects, and consequences as experience accrues, 3. Reconciliation of “what could happen” (as determined by RCM analysis) with “what did happen” (from day-to-day experience), will encourage maintenance staff at all levels to acquire a deeper understanding of the failure modes and effects related to each significant system, 4. Changes in operating context , will be rendered obvious and inspire adjustments to the assumptions and approximations of the initial RCM analysis , and 5. A valuable intellectual asset “the reliability database” will flourish as a an ever-evolving source of data and practical knowledge for implementing effective reliability improvement. The integration of RCM philosophy into the processes surrounding the CMMS will demand thought and discussion. Furthermore, it will require the RCM education of each party to the project: that is, the users, the managers, and the IT personnel charged with implementing the necessary program modifications.

Do you have any comments on this article? If so send them to murray@omdec.com.

References

F. Stanley Nowlan, Howard F. Heap, Reliability-Centered Maintenance, United Airlines under the sponsorship of the Office of Assistant Secretary of Defense (Manpower, Reserve Affairs and Logistics), 1978

[1] Ending in either functional or potential failure. It is not a requirement that the asset must proceed to functional or catestrophic failure. See Interview with Dr. Dragan Banjevic.