EXAKT

EXAKT is a decision support tool for predicting reliability and optimizing condition based maintenance. Read more...

EXAKT predicts equipment failure, estimates remaining useful life of equipment and defines the mix of preventive replacement and run to failure in order to:

- Optimize costs

- Optimize reliability

EXAKT integrates your data from ALL your data bases and then uses it to make optimal decisions!

- Achieve the optimum risk/cost/reliability balance

If you are a CEO, CFO, Plant Manager, Supervisor, Maintenance Manager, Engineer, Reliability Expert or Technician in:

-

Mining

-

Petrochemical and Refining, Oil and Gas

-

Chemicals

-

Utilities

-

Metal Processing, Steel and Plastics

-

Pulp and Paper, forest products

-

Heavy Transportation

-

Food and Beverage processing

-

Municipal, State and Federal Departments, Military and

-

basically any industry where asset replacement or equipment failures are expensive

you can rely on EXAKT answering the question:

“Can we finish this production run before a breakdown?”

It provides you with

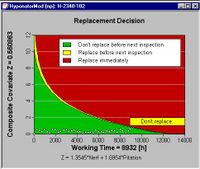

A Replacement Decision Report

All that collected data now actually means something!

The report tells you what action to take in one uncomplicated chart!

No need to look at scores of charts and graphs, wondering what it all means.

If the current composite variable - represented by the latest white dot – is in the green, you’re safe until the next inspection period. If it’s in the yellow, repair it before the next inspection period. In the red field, act immediately.

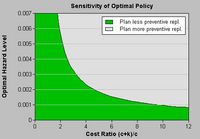

A Sensitivity of Optimal Policy Report

Get the RIGHT information at the RIGHT time!

It reveals how important accurate cost data is to the ultimate replace–or-don’t-replace decisions and

Shows how the cost-data precision affects the hazard level (the level at which a replacement is recommended), and whether you should plan less, or more, preventive replacements.

The curve shows that at a low cost ratio one would plan less preventive replacements. Where cost ratio is high, one would plan to replace preventively more often.

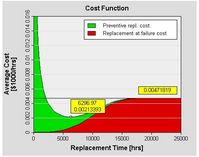

A Cost Function Report

Age-based Weibull analysis can be effectively used to deliver vital decision-making results on its own if you don’t have condition data

The green area illustrates the costs that are associated with preventive replacements. The “dot” shows the recommended, and lowest-cost, point for replacement…every 6297 hours. The red area shows the not preventively-replaced (i.e., failure-replaced) components’ contribution to the total cost of replacement.

Maintenance cost reductions of 10 to 49% per failure mode!

84 to 100% reduction in failures!

Benefits

- Relates condition variables to failure modes with statistical confidence levels and therefore prompts the company to stop collecting and analysing low-impact data

- Gives the equipment operator a high level of confidence that the equipment will not fail before the end of the production run

- Reduces maintenance costs by optimizing the blend of preventive replacements and run to failure

- Provides for orderly replacement planning by predicting remaining useful life

- For complex equipment, increases the accuracy of failure prediction by operating at the component level

- Provides accurate and consistent prediction model for each piece of equipment

- easy to read graphical output shows results at a glance

Sample Results:

- Maintenance cost reductions of 10 to 49% per failure mode

- 84 to 100% reduction in failures

- Consistently statistically significant confidence levels

If you have any question or need more information please contact Claudia Krueppel claudia@omdec.com or call her under Tel. +49 170 9674101.

Please download the brochure.