Using EXAKT and Weather Conditions to reduce failures in a Wires network

Utilities case study...

SUMMARY:

In this project, the customer runs a large network of above-ground wires to generate revenues for its many customers. Supply interruptions not only cause loss of revenue, but are expensive to fix and are the cause of much negative publicity. Two dominant failure modes were identified for the network – equipment failure and trees falling on the lines. The tree-falls were selected as the focus of the project to see if EXAKT could correlate weather data with failures and provide a predictive model. The purpose of the model was not so much to prevent failure (preventing bad weather proved to be beyond the capabilities of EXAKT!) but to allow the company to provide a rapid and cost effective response to both impending failure and actual failure. The project proposed two key responses – first to predict where the failures would shortly occur based on the analysis of the weather data and therefore to pro-actively trim the trees; and second to have a fast dispatch capability the most likely trouble spots to mitigate the consequential costs of failure when failure does occur. Anecdotal evidence suggests that the annual savings are in the millions of dollars.

BACKGROUND AND OBJECTIVES:

The company’s wires network is very extensive and delivers to consumers over a wide area. Numerous failure modes had been identified for the network, of which equipment failure and trees falling on the wires consisted of about 60%. Repair costs were very high – often due to the bad weather which was a significant cause of the failures, but also because of the remote locations involved. By definition, trees-falling will occur more frequently in heavily wooded areas – and these are the typically most remote areas.

The company had been collecting readings relating to the failures consistently about for three years, and had amassed data on over 100,000 interruptions. The data was structured by location, duration, hours to repair and severity in terms of how many customers were affected. At the same time, data was available from the weather bureau relating to the frequency and severity of those types of weather that could be expected to affect the frequency of failure.

By correlating the failure data with the location of the failures and the weather conditions, the customer set the objectives as:

1. to determine which weather patterns most significantly impacted on failure.

2. to establish whether there was a combination of frequency, severity and weather type which could be used to predict where the failure probability was highest – so as to reduce the incidence of failure by pro-active tree cutting.

3. to use the same predictive methodology to dispatch a rapid response team to the most likely problem areas in the event of unexpected bad weather.

4. to determine whether significant increases in customer satisfaction and reduction in costs could be achieved.

METHODOLOGY:

Because of the huge volume of data available, the first steps concentrated on data reduction and amalgamation. Wires were divided into categories by carrying capacity; suspensions (ie taken out of service with no-fault) were eliminated; geographical areas were delineated with similar operating and weather conditions. Three heavy interruption areas acted as the focal point of the project, with two light interruption areas to serve as the control.

Each failure was then tracked for these five areas – with the output of this process being an event table. This tabulates the date and nature of the failure (the failure mode) and summarizes according to whether it is a Functional Failure (ie an interruption of the desired service), a Potential Failure (a condition which, if not corrected, will deteriorate into a Functional Failure) or a Suspension (withdrawal from service for reasons other than failure – these need to be eliminated from the failure analysis process).

Next the weather data was examined; weather variables such as wind speed and wind direction, snow amounts, freezing rain, thunderstorms, humidity, temperature and pressure were all considered as potentially significant. Dimension reduction techniques were used to assemble the data into usable packets – hourly and daily data were transformed into meaningful weekly data; multiple actual wind and temperature readings became max, min and averages, plus the amount of a rise or drop. And so on.

From this mass of data, EXAKT was then used to perform the proportional hazards modeling. This is an automatic process by which non-significant variables can be eliminated if they have no impact on the model’s ability to predict failure. Given the huge number of variables, EXAKT handled over 700 PHM iterations before the best-fit models were decided on.

Because the location and the type of wires varied from sector to sector, different models were developed for different sectors – but all useable models must pass the 95% confidence level test (ie the results are expected to be accurate 19 time out of 20). One effective model for example combined wind speed and wind direction. A second model included the maximum jumps in temperature and pressure. On the other hand, maximum temperature itself was not a significant co-variate.

The fact that different models can be developed for each of the sectors strengthened the project as it means that the maintenance response can be tailored for each sector individually. All data used for the multiple models is drawn from the single database, with EXAKT taking on the task of applying the data to the specific model.

RESULTS:

The immediate output for the customer is a series of EXAKT graphs which will – for each of the network sectors – provide an insight into where the problems are and will soon be.

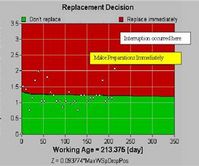

In this sample output graph, the key variable was the drop in the maximum wind speed, and provided a reliable predictor of failure in the sector for which the model was developed. The dotted line shows the plot for the variables in the model, and the summary message from the model is to prepare the response team immediately (and in practice the interruption occurred within a very few days of the warning).

As long as the actual readings are in the Green zone, then no immediate action need be taken. However once the actual records cross into the Red zone, then the model is advising that immediate action should be taken to avoid the problem.

Underlying the use of the model is the application of costs. One of the outputs of EXAKT is to propose the optimum balance between preventive work and run to failure. Effective management of this option requires the calculation of cost data for the preventive work and for the failure. In this case, the failure costs were extremely high – in the range of 100 to 300 times the cost of the preventive work – and sometimes much higher. Applying these cost ratios of 100:1 up to 300:1, EXAKT predicted that cost savings from 9% to 23% would have been achieved if the model had been applied to the past occurrences of failure. In reality, one serious ice storm will drive the repair costs to many thousands of times the preventive costs.

A further output from the EXAKT model is to estimate the mean time between failure (MTBF) of each of the equipments and wires. Comparing the data for the heavy interruption area and the light interruption area, the ratio of the MTBF’s is about 5:1 – ie the frequency of failure in the heavy interruption areas is about five times that in the light interruption areas.

This combination of outputs – failure prediction, cost reduction opportunities and MTBF – thus provides the basis for the maintenance team to significantly improve the management of their assets.

NEXT STEPS:

While the project was adjudged to be a success, and the weather data now forms an integral part of the maintenance planning process, management wishes to extend the process forward in a couple of important new ways:

1. Currently only the historical weather patterns have been used to identify the probability of failure in the high-failure sectors. Using the same variables, but weighting them to account for short-term weather forecasts is the next step. This will add an improved predictive capability to the preventive actions.

2. With the huge amount of data that is current available, the customer has used EXAKT only for specific project-focused interrogations of the data. With the introduction of the new REWOP (Reliability Engineering Workbench OPtimizer), automatic integrations already exist into databases such as SAP, Ellipse, Maximo, Oracle, Datastream and others, as well as the condition monitoring databases for oil analysis, vibration etc. This means that database enquiries can be seamlessly accommodated, plus the EXAKT models can be automatically updated each time new data is entered into the original work order and condition monitoring databases. EXAKT is now an on-line tool.

3. In addition, REWOP has a large number of built-in key performance indicators which will help management track the actual results against their projections. Alongside this is a powerful drill-down capability that will allow management to view data from the highest level of summarization through the intermediate layers down to the initial weather, work order or condition data.