AGE/CON solves Vehicle Replacement problem for Container Terminal Company

In implementing AGE/CON, company management has introduced an analytical tool which is guiding their equipment replacement decisions, and feeding their capital budgeting process. In addition, for a fleet of 20 Hustler tractors, changing the replacement policy from 12 years to 9 years would save over $110,000.

SUMMARY:

In 2005, when one of North America’s largest Container Terminal companies decided to introduce a systematic vehicle replacement policy, it turned to Dr Andrew Jardine from the University of Toronto. Dr Jardine’s book “Maintenance Replacement and Reliability”* is the basis for the software program AGE/CON which many companies have used to decide the optimum time to replace vehicles. By applying the software, the Marine Terminal company was looking to achieve specific results:

- To build a vehicle replacement policy based upon sound economics

- To implement a replacement policy for vehicle replacement at their lowest economic average cost

- To provide the right information for preparing capital budgets

- To reduce overall fleet costs

BACKGROUND AND OBJECTIVES:

With over 2500 vehicles in total, including forklifts, yard tractors, container handling equipment, mobile cranes and pickup trucks, the company depends heavily on mobile equipment to keep its operations running smoothly. While some of the equipment is up to 30 years old, the average age is about 8 to 10 years; assessing the best time to trade the vehicles has a significant impact on both the capital and operating cost of the business.

The basic problem centers around how to integrate the various cost and value elements that are involved in the vehicle replacement decision:

1. the original and replacement cost of the asset,

2. the trade-in or disposal value or cost

3. the trends in operations and maintenance costs

4. the discount rates to be used for the changing value of money

5. the utilization rates of the vehicles – be they constant or variable

6. the tax rules and the inflation rates

METHODOLOGY:

Company management started their quest by attending a one-day seminar by Dr Jardine focusing on optimal replacement decision-making. Most of the core data was readily available, plus the program was self- installing; this meant that the initial results could be quickly and easily obtained.

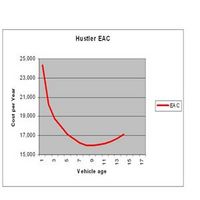

The early trials were focused on the highest cost assets, with the objective of finding the optimum economic life for the equipment. This corresponds to the point at which the average cost of the vehicle is at its lowest – representing the optimum point for replacing the equipment. Before or after that point, the economic average cost rises – indicating the company is incurring higher overall costs. As market conditions change, so the economic model will also change – for example the trade in values and the replacement costs will vary, interest rates will change. This is accommodated by simply re-running the model with the modified values and costs.

RESULTS:

While it is premature to assess the full cost savings from what is a longer term capital replacement process, management already sees significant value in the use of the software:

- Capital expenditure guidelines are now available based on sound economic reasoning

- AGE/CON is the a primary input tool for planning equipment replacements in the capital budgets

- The techniques behind the software have played a key role in educating decision-makers about the variables involved in making optimal replacement decisions

- For a fleet of Hustler container tractors, AGE/CON shows the optimum replacement at 9 years (see graph below). For a fleet of 25 vehicles, a 9 year replacement policy saves the company over $135,000 compared to 12 year replacement. This is equivalent to two free tractors.

MANAGEMENT’S COMMENTS:

AGE/CON is providing “high value” and “is being used to feed our capital budgeting process”. Overall, the product was “certainly worth the cost…. For the first time ever, we have an analytical tool to guide us in equipment replacement decision making.”

NEXT STEPS:

With the success of this program to date, company management plans to extend its usage to a wider range of equipment classes. Future developments of the software are expected to add new functionality which will broaden its application.